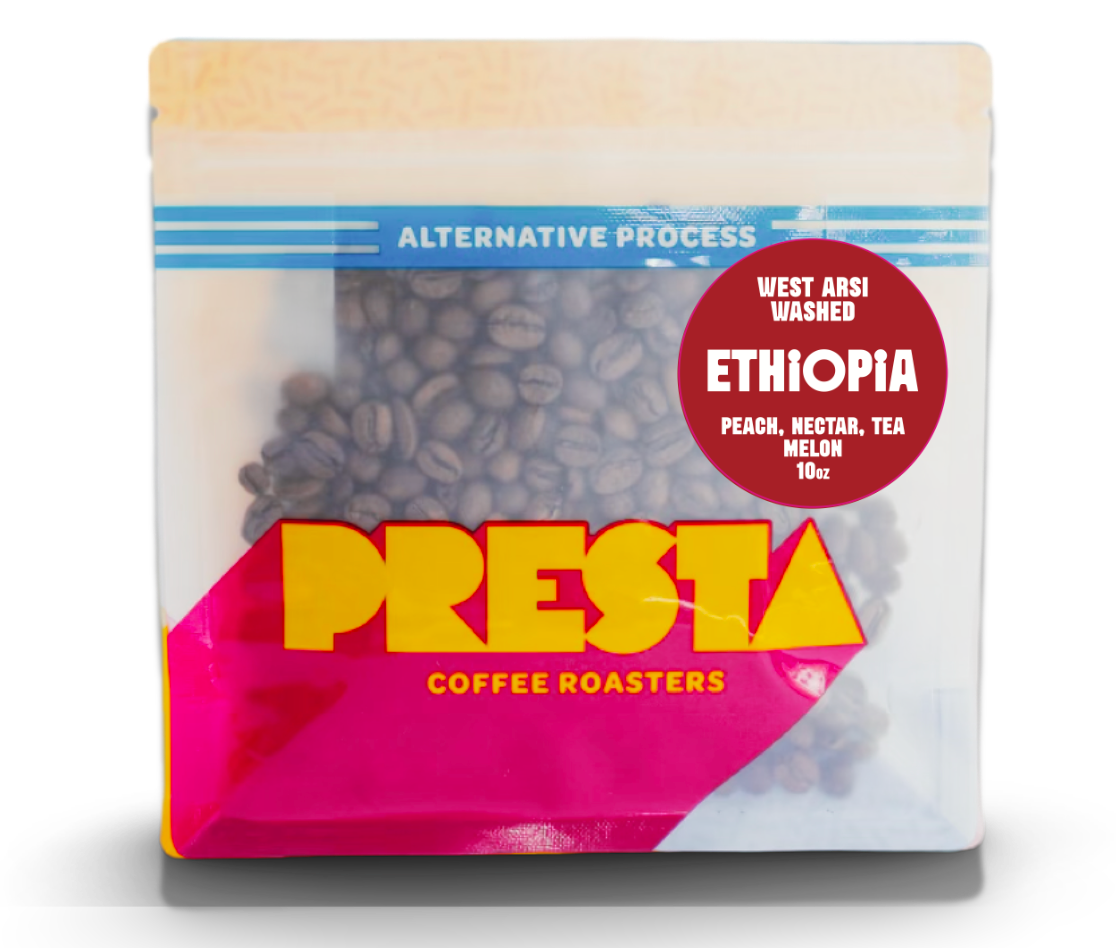

Ethiopia - West Arsi - Washed

Country: Ethiopia

Zone: West Arsi, Nensebo

Growing Region (ECX): Sidama

Producer: 742 Smallholder Farmers

Processing Facility: Refisa Washing Station

Variety: 74110, 74112

Tasting Notes: Peach, Nectar, Tea, Melon

This coffee was sourced from Snap Specialty Coffee (through Ally Coffee Importers). Snap was established in 2008 by Negusse Debela in Ethiopia’s capital, Addis Ababa and now the company operates three washing stations in the Gedeo zone, and partners with additional washing stations in Uraga, Guji, and Nensebo, like the washing station that this coffee is from, in Refisa. This region is also referred to as the Sidama (Sidamo), classified by the Ethiopian Commodity Exchange (ECX), where the coffee was produced by 742 smallholder producers living in the nearby the Refisa Washing Station. The farmers grow locally selected varieties 74110 and 74112, which were developed by the Jimma Agricultural Research Center (JARC) in the 1970s.

The washed process is when the coffee cherries have the skin, fruit mucilage, and parchment layer removed shortly after picking. The cherries are initially sent through a de-pulper(machine) to remove the skin and majority of the mucilage before being soaked in large tanks to loosen the mucilage that remains attached and allow for some very simple fermentation of the remaining fruit sugars, the beans are then flushed aggressively with water to rinse them clean before the drying phase. Drying can be done in a variety of ways, large industrial dryers for faster drying in less sunny places with high humidity, or more often it will be spread on large concrete pads where the coffee needs to be turned by hand (or rake) to ensure consistent drying. Finally the coffee is sent through a dry mill to remove the final protective layer around the beans, the parchment layer. Once the parchment is removed the beans are ready for sorting and grading.

These cherries are manually harvested, always being picked at the peak of their ripeness, before being delivered to the washing station. This washed processing begins with pulping the cherries and placing them into fermentation tanks where they are fermented in water for 48–60 hours. The fermented coffee is then washed, and the parchment coffee is dried on the station’s 200 raised beds for 7–10 days until reaching its ideal humidity. The raised beds encourage faster drying by allowing airflow above and below the layers of coffee beans, and the short fermentation and drying time leads to delicate sweetness of a (not southern) peach tea. This coffee also has exceptional complexity for a washed coffee because it is from smallholder farms instead of a larger single farm.